- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

High Quality Non-Stick Enamel Cast Iron Dutch Oven | Casserole

Aug . 10, 2025 09:40

The Unparalleled Performance of High-Quality Non-Stick Enamel Cast Iron Cookware in Modern Cuisine

In the sophisticated landscape of culinary arts and advanced kitchen solutions, the demand for superior-performing cookware is unwavering. Among the myriad options available, the High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole stands out as a pinnacle of durability, thermal efficiency, and aesthetic appeal. This product category, bridging traditional craftsmanship with modern innovation, is crucial for both professional chefs and discerning home cooks who prioritize consistent results and longevity in their cooking implements. Cast iron, known for its exceptional heat retention and even heat distribution, is elevated further by the application of a high-quality enamel coating. This enamel not only provides a naturally non-stick surface, reducing the need for excessive oils and fats, but also offers unparalleled corrosion resistance, protecting the underlying iron from acidic foods and preventing rusting. The strategic integration of these material properties ensures a cookware piece that is not only highly functional but also remarkably easy to clean and maintain, a significant advantage in high-volume culinary environments. Furthermore, the inherent robustness of cast iron means these Dutch ovens and casseroles are built to last for decades, often becoming cherished heirloom pieces that withstand the rigors of daily use. Beyond its functional benefits, the vibrant array of colors and finishes available in high-quality enamel cast iron cookware makes it an attractive centerpiece for any kitchen, allowing for seamless transition from stovetop or oven to table serving. This versatility, combined with their ability to perform a wide range of cooking tasks—from slow braising and stewing to baking bread and roasting meats—underscores their indispensable value. As culinary trends lean towards healthier cooking methods and greater sustainability, the non-stick and durable attributes of enamel cast iron align perfectly with these evolving consumer preferences, marking it as a critical asset in the modern kitchen arsenal. Our focus delves into the technical specifications, manufacturing prowess, and diverse application scenarios that define the excellence of this essential culinary tool, affirming its position as a wise investment for any serious cook or culinary professional seeking to elevate their cooking experience. The commitment to delivering a truly superior product involves meticulous attention to material selection, advanced casting techniques, and rigorous quality control, all culminating in a cookware solution that consistently outperforms expectations.

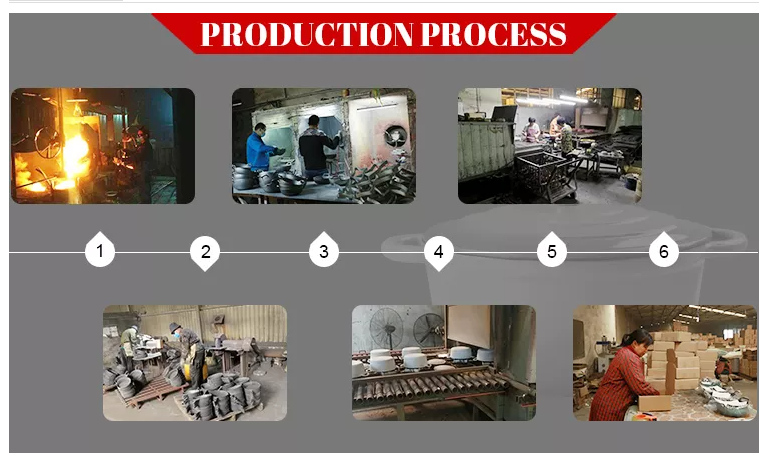

Precision Manufacturing: The Detailed Process Flow of Enamel Cast Iron Cookware

The production of a High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole is a complex, multi-stage process that combines traditional metallurgical techniques with advanced industrial precision, ensuring both structural integrity and a flawless aesthetic finish. The journey begins with the selection of premium-grade raw materials, primarily high-purity pig iron and recycled cast iron scrap, meticulously chosen for their optimal carbon content and minimal impurities. This raw material is then melted in induction furnaces, allowing for precise temperature control and alloying element additions, crucial for achieving the desired microstructure and mechanical properties of the cast iron. Following melting, the molten iron is poured into sand molds, a process known as sand casting. This method, while labor-intensive, allows for the creation of intricate shapes and varying wall thicknesses necessary for optimal heat distribution in cookware. After cooling and solidification, the raw cast iron pieces are extracted from the molds, and excess metal (flash) is removed through a process called fettling. This involves grinding and blasting to smooth out rough edges and prepare the surface for subsequent treatments. Surface preparation is critical for enamel adhesion; the cast iron pieces undergo thorough cleaning and shot blasting to create a perfectly clean, slightly roughened surface profile. The enameling process then commences, typically involving multiple layers of vitreous enamel. The first layer, often referred to as the ground coat or prime coat, is applied and then fired at extremely high temperatures (around 700-800°C), creating a strong chemical bond with the cast iron. This layer is crucial for corrosion protection and serves as a base for subsequent decorative layers. Subsequent cover coats, which provide the desired color and non-stick properties, are then applied and fired. Each layer requires precise temperature and time control during firing to achieve a durable, chip-resistant, and aesthetically pleasing finish. Throughout the entire manufacturing process, stringent quality control measures are implemented. These include spectroscopic analysis of raw materials, ultrasonic testing for internal defects in castings, dimensional checks, adhesion testing for the enamel layer (e.g., cross-cut test, impact resistance), and color consistency checks. Products typically adhere to international standards such as ISO 9001 for quality management systems and ANSI standards for material specifications. The inherent durability of High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole ensures an exceptional service life, often extending beyond several decades with proper care. These attributes make them ideal for a wide range of industries beyond just home kitchens, including professional catering, restaurant chains, and even specialized food processing applications where consistent, even heating and robust equipment are paramount. Their high thermal mass also contributes to energy efficiency, reducing overall energy consumption during cooking, while the superior enamel coating provides excellent resistance to corrosion from acidic ingredients, extending product lifespan and maintaining hygienic surfaces.

Illustrative diagram of the enamel cast iron manufacturing process, highlighting key stages from raw material to finished product.

Navigating Industry Trends and Evolving Market Dynamics for Enamel Cast Iron Cookware

The global cookware market is experiencing significant shifts driven by evolving consumer preferences, technological advancements, and a heightened focus on sustainability. Within this dynamic environment, the market for High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole is witnessing robust growth, propelled by several key industry trends. Firstly, there is a pronounced trend towards healthier cooking, which directly favors non-stick surfaces that minimize the need for excess fats and oils. Enamel cast iron naturally supports this trend by offering a safe, PFOA-free non-stick solution. Secondly, consumers are increasingly demanding durable, long-lasting products that offer excellent value for money over their lifetime, moving away from disposable goods. The inherent longevity and robust construction of High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole align perfectly with this sustainability-driven purchasing behavior. Data from market research firms such as Grand View Research and Statista indicate a steady CAGR for the global cookware market, with premium segments, including cast iron, showing particularly strong performance. This growth is also fueled by the increasing popularity of home cooking, amplified by recent global events, and the rise of culinary content online, which showcases diverse cooking techniques that benefit immensely from the thermal properties of cast iron. Technologically, advancements in enameling processes are leading to even more durable, chip-resistant, and aesthetically diverse coatings. Manufacturers are now able to produce a wider spectrum of colors and unique finishes, appealing to modern kitchen aesthetics and allowing for greater product differentiation. Furthermore, innovations in mold design and casting techniques are resulting in lighter yet equally robust cast iron pieces, improving handling and usability without compromising performance. Environmentally, the use of recycled cast iron in production and the product’s long lifespan contribute positively to reducing waste, making it a more eco-conscious choice compared to less durable alternatives. The market is also seeing increased demand for versatile cookware that can perform multiple functions—from stovetop searing to oven baking and even induction cooking. High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole excels in this area, making it a highly attractive investment for both consumers and professional establishments. This comprehensive understanding of market dynamics allows manufacturers to strategically adapt their product offerings, focusing on quality, innovation, and sustainability to meet and exceed the evolving expectations of a discerning global clientele.

Comprehensive Technical Specifications and Performance Parameters

Understanding the intrinsic technical parameters of a High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole is paramount for B2B decision-makers seeking reliable and efficient culinary solutions. The performance of these products is not merely anecdotal but rooted in quantifiable engineering and material science. At its core, the material composition consists of high-grade grey cast iron (typically ASTM A48 Class 30 or higher), chosen for its excellent thermal conductivity and high specific heat capacity, ensuring even heat distribution across the cooking surface and superior heat retention. This prevents hot spots, promoting uniform cooking and browning. The non-stick enamel coating is composed of a vitreous enamel, a type of glass fused to the iron at high temperatures. Key properties of this enamel include a Mohs hardness typically ranging from 5 to 6, indicating good scratch resistance, and an operating temperature range often up to 260°C (500°F) for general use, with higher thermal shock resistance for oven use. The thickness of the enamel layer usually ranges from 0.3mm to 0.8mm across multiple coats, optimized for durability and non-stick performance without compromising heat transfer.

| Parameter | Typical Value / Range | Benefit / Description |

|---|---|---|

| Material (Core) | Grey Cast Iron (ASTM A48 Class 30-40) | Superior heat retention and even heat distribution. |

| Enamel Coating Type | Vitreous Enamel (Lead & Cadmium Free) | Durable, non-reactive, easy-release, food-safe, colorful finish. |

| Enamel Hardness | 5-6 Mohs Scale | Good resistance to scratches and abrasions. |

| Max. Oven Temperature | Up to 260°C (500°F) or higher depending on knob material | Versatility for baking, roasting, braising in oven. |

| Thermal Shock Resistance | ΔT > 150°C (302°F) | Withstands rapid temperature changes without cracking. |

| Acid/Alkali Resistance | High (pH 1-14, excluding strong hydrofluoric acid) | Prevents corrosion from acidic foods (e.g., tomatoes, wine). |

| Compatibility | All stovetops, including Induction, Oven, Grill | Universal applicability across different cooking methods. |

| Capacity Range | Typically 2 Liters (2.2 Qt) to 7 Liters (7.4 Qt) | Varied sizes to suit different serving needs and culinary tasks. |

| Weight (Approx.) | 3 kg (6.6 lbs) to 8 kg (17.6 lbs) depending on size | Reflects material density, contributes to heat retention. |

| Certifications Adhered To | FDA, Prop 65, LFGB, ISO 9001 (for manufacturing) | Ensures safety, quality management, and compliance with international standards. |

The detailed parameters above illustrate that the selection of a High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole is a technical decision, not merely an aesthetic one. The superior thermal conductivity of cast iron ensures that heat is absorbed quickly and distributed evenly across the entire surface, from the base to the sidewalls, preventing localized burning and promoting consistent cooking. This uniformity is particularly critical for delicate sauces, braised dishes, and baking, where precise temperature control is paramount. The high thermal mass of cast iron also means it retains heat for extended periods, even after being removed from the heat source. This passive cooking capability is not only energy-efficient but also ideal for keeping food warm for serving and for slow-cooking methods that benefit from sustained, gentle heat. The vitreous enamel coating, while providing non-stick benefits and ease of cleaning, is also highly resistant to thermal shock, acid, and alkali, making it suitable for cooking a wide variety of ingredients, including highly acidic ones like tomatoes or citrus, without reacting or leaching metals into the food. This chemical inertness ensures food safety and preserves the true flavors of ingredients. Manufacturers committed to producing High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole adhere to strict quality control protocols, including material analysis, dimensional accuracy checks, and comprehensive testing for enamel adhesion and durability. These rigorous standards ensure that each product not only meets but exceeds industry benchmarks for performance and longevity, providing a reliable and robust solution for demanding culinary environments. Investing in cookware that meets these specifications translates directly into enhanced cooking results, reduced energy consumption, and long-term cost savings through unparalleled durability.

A visual representation highlighting the meticulous technical specifications that define premium enamel cast iron cookware.

Versatile Application Scenarios and Distinct Technical Advantages

The inherent design and material advantages of a High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole render it exceptionally versatile across a multitude of culinary applications, from professional restaurant kitchens to specialized catering services and even high-end domestic use. In commercial kitchens, their robust construction makes them ideal for high-volume, continuous use, enduring the harsh demands of daily operations. They are indispensable for slow-cooking techniques such as braising meats, simmering rich stews, and developing complex flavors in stocks and sauces, where their unparalleled heat retention ensures consistent, gentle cooking over extended periods. For baking, particularly artisan breads like sourdough, the heavy cast iron lid creates a perfect steamy environment, mirroring a professional bread oven and resulting in a crisp, golden crust and a tender crumb. Furthermore, the even heat distribution is crucial for roasting larger cuts of meat and poultry, ensuring uniform cooking from edge to center and achieving perfect caramelization. The non-stick properties of the high-quality enamel surface not only facilitate easy food release but also significantly simplify cleanup, a critical time-saving factor in busy culinary environments. This non-stick attribute also promotes healthier cooking by reducing the need for excessive cooking fats. From a technical advantage perspective, the sheer thermal mass of the High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole means it absorbs a tremendous amount of heat energy and releases it slowly and consistently, which is a major contributor to energy efficiency. This sustained heat significantly reduces the energy required to maintain cooking temperatures, leading to lower utility costs in professional settings. Moreover, the superior enamel coating acts as a formidable barrier against corrosion, even when exposed to highly acidic ingredients like tomatoes, vinegars, or wines over prolonged cooking times. Unlike raw cast iron, which can react with acidic foods and leach iron, the enamel ensures a non-reactive cooking surface, preserving the true taste of ingredients and preventing metallic off-flavors. This corrosion resistance also extends the product's lifespan dramatically, safeguarding the investment for B2B purchasers. The durability is further enhanced by its resistance to chipping and scratching, maintaining its aesthetic and functional integrity through years of heavy use. The comprehensive compatibility with all heat sources, including induction cooktops, ovens, and grills, underscores its adaptability, making it a universal tool suitable for modern kitchen setups. These combined technical advantages make the High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole an indispensable asset for any culinary professional or establishment focused on efficiency, quality, and longevity.

Illustrating diverse culinary applications where the superior heat retention and non-stick properties of enamel cast iron excel.

Strategic Vendor Selection: Differentiating Manufacturers and Customization Potentials

For B2B entities, the process of selecting a manufacturer for High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole extends far beyond simple price comparison; it involves a meticulous evaluation of technical capabilities, quality assurance, ethical sourcing, and the capacity for customization. Reputable manufacturers differentiate themselves through a transparent commitment to material sourcing, utilizing only virgin pig iron and certified recycled materials that meet stringent purity standards, ensuring the final product's metallurgical integrity and safety. Their manufacturing facilities typically boast ISO 9001 certifications, signifying robust quality management systems that govern every stage from casting to enameling and final inspection. This level of quality control is non-negotiable for products destined for commercial use, where performance reliability directly impacts operational efficiency and brand reputation. Furthermore, leading manufacturers invest heavily in research and development, constantly refining their casting techniques to reduce porosity and improve structural uniformity, and innovating in enamel formulation to enhance non-stick properties, chip resistance, and aesthetic durability. This continuous improvement ensures that their High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole products remain at the forefront of industry standards.

A critical factor in B2B procurement is the manufacturer's ability to provide comprehensive customization solutions. This capability is vital for brands looking to offer unique product lines or for hospitality groups requiring bespoke cookware that aligns with their specific aesthetic or functional needs. Customization options for High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole can encompass a wide array of features. This includes tailored capacities and dimensions, allowing clients to specify volumes and shapes that perfectly suit their menu requirements or kitchen space constraints. Surface finishes and color palettes are highly customizable, offering an extensive range of enamel colors, gradients, and even matte or glossy textures to match specific brand aesthetics or interior designs. Furthermore, the inclusion of custom branding, such as embossed logos on lids or bases, provides a powerful avenue for corporate identity reinforcement. Technical modifications are also feasible, such as specialized handles designed for ergonomic comfort in professional use, enhanced lid designs for improved condensation management, or specific knob materials (e.g., stainless steel for higher oven temperatures). The ability to prototype custom designs and conduct rigorous testing before full-scale production is a hallmark of a truly capable manufacturer. This ensures that customized products not only meet visual specifications but also maintain the high performance and durability expected from High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole. Engaging with a manufacturer who demonstrates a deep understanding of these technical and aesthetic customization possibilities is crucial for businesses aiming to distinguish their offerings in a competitive market. A robust partnership with such a vendor ensures not only the procurement of high-quality products but also the strategic advantage of unique, purpose-built cookware solutions. This emphasis on flexibility and technical partnership underscores the importance of a holistic approach to vendor selection in the B2B cookware sector.

Exploring the vast possibilities of customization for enamel cast iron cookware, from color to ergonomic design.

Real-World Impact: Application Cases and Success Stories

The tangible benefits of investing in High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole are best illustrated through real-world application cases that highlight their performance and contribution to operational excellence. Consider a premium chain of farm-to-table restaurants that transitioned their entire braising and stewing operations from conventional stainless steel pots to High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole units. Before the switch, they faced issues with uneven cooking, requiring constant stirring, and difficulty in achieving consistent caramelization and tenderization of meats. After implementing the enamel cast iron cookware, they observed a significant improvement in dish consistency, with meats becoming uniformly tender and sauces developing richer, more complex flavors due to the stable, even heat distribution. This not only enhanced the quality of their signature dishes but also reduced labor costs associated with monitoring and stirring. Another compelling case involves a large-scale catering company that needed robust, versatile cookware capable of transitioning seamlessly from stovetop to oven to serving line for large events. Their previous aluminum and non-stick coated pots showed rapid wear and tear, and issues with heat retention for buffet service. By adopting High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole, they achieved superior heat retention, ensuring food remained at optimal serving temperatures for longer periods, reducing the need for continuous reheating and thereby lowering energy consumption. The durable enamel coating also withstood the rigorous cleaning cycles of commercial dishwashers, significantly extending the lifespan of their cookware inventory and reducing replacement costs by an estimated 30% annually. A final example highlights a boutique bakery specializing in artisan sourdough breads. They struggled to replicate the ideal crust development found in traditional brick ovens using standard bakeware. Upon incorporating specifically designed round High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole for their bread baking, the heavy lid effectively trapped steam, creating the perfect humid environment essential for a blistered, crackling crust and an airy crumb. This direct application of their thermal properties transformed their bread quality, leading to increased customer satisfaction and market differentiation. These cases unequivocally demonstrate that the investment in high-quality enamel cast iron cookware delivers measurable returns through improved culinary outcomes, enhanced operational efficiency, and long-term cost savings, making them a strategic asset for any food service enterprise.

Illustrating a success story where high-quality enamel cast iron cookware elevates culinary operations and efficiency.

Assurance of Quality: Certifications, Warranty, and Customer Support

In the B2B landscape, trust is built on demonstrable quality and reliable support. For High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole, this means adherence to rigorous international standards and a transparent commitment to customer satisfaction. Manufacturers of premium enamel cast iron cookware typically hold certifications such as ISO 9001:2015, affirming their robust quality management systems throughout the design, production, and delivery processes. Beyond this, product-specific certifications are crucial: FDA (Food and Drug Administration) compliance for materials and coatings, ensuring they are food-safe and non-toxic; LFGB (Lebensmittel-, Bedarfsgegenstände- und Futtermittelgesetzbuch) compliance for German and European markets, guaranteeing absence of harmful substances; and California Proposition 65 compliance, indicating products are free from listed chemicals known to cause cancer or reproductive harm. These certifications provide an authoritative guarantee of product safety and quality. The delivery cycle for B2B orders is managed with precision, typically involving detailed logistics planning from order confirmation to shipment tracking. For standard products, lead times generally range from 4-6 weeks for manufacturing, with additional time for international shipping depending on destination. For customized orders, this timeline may extend to 8-12 weeks due to specialized tooling and prototyping requirements. Transparent communication regarding delivery schedules and potential unforeseen delays is paramount, ensuring clients can plan their operations effectively. A comprehensive warranty commitment is a hallmark of a trustworthy manufacturer. High-quality enamel cast iron cookware often comes with a limited lifetime warranty against manufacturing defects, underscoring the manufacturer's confidence in their product's durability and craftsmanship. This warranty typically covers defects in materials and workmanship, such as chipping, cracking, or peeling under normal use, demonstrating a long-term commitment to product performance and customer investment. Exclusions usually apply to damage from misuse, drops, extreme thermal shock, or commercial dishwasher use if not explicitly rated. Complementing these assurances is a dedicated customer support framework. This typically includes multi-channel support (phone, email, online portal) for technical inquiries, product maintenance guidance, and order-related assistance. Providing detailed use and care instructions is crucial for maximizing product longevity and preserving warranty validity. Manufacturers often offer resources such as online FAQs, downloadable guides, and video tutorials to empower users with the knowledge to properly maintain their High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole. This holistic approach to quality, delivery, and support builds enduring trust and reinforces the value proposition for B2B partners.

Frequently Asked Questions (FAQ) for Enamel Cast Iron Cookware Procurement

Navigating the procurement of specialized cookware like High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole often raises specific technical and logistical questions for B2B buyers. Below are some of the most frequently asked questions, addressed with expert insights to facilitate informed decision-making and ensure optimal utilization of these premium products.

Q1: What are the primary advantages of enamel cast iron over traditional non-stick coatings for commercial use?

A1: The advantages are multi-faceted and crucial for commercial environments. Firstly, the non-stick property of enamel is achieved through the smooth, glass-like surface of the vitreous enamel, which is inherently durable and does not degrade or flake off over time like many PTFE-based traditional non-stick coatings, especially under high heat or abrasive use. This eliminates concerns about chemical leaching (PFOA/PFOS) that have historically been associated with some synthetic non-stick surfaces. Secondly, enamel cast iron offers superior heat retention and distribution due to its high thermal mass, which is critical for consistent cooking results in high-volume kitchens and energy efficiency. Traditional non-stick pans, often made of aluminum with a thin coating, heat up quickly but lose heat just as fast, leading to temperature fluctuations. Thirdly, enamel is highly resistant to acidic foods and corrosion, unlike seasoned cast iron or some metallic non-stick pans, meaning it will not react with ingredients or rust, preserving food integrity and product longevity. This also allows for easier cleaning and eliminates the need for re-seasoning. Lastly, the robust construction of High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole ensures a significantly longer lifespan compared to most conventional non-stick cookware, which typically has a limited operational life in demanding commercial settings due to coating degradation.

Q2: How does the quality of enamel affect the durability and lifespan of the product?

A2: The quality of the enamel coating is perhaps the most critical determinant of a High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole's durability and lifespan. High-quality enamel is characterized by a multi-layer application process, typically involving a ground coat and multiple cover coats, each fired at precise, extremely high temperatures. This creates a strong, inseparable bond with the cast iron substrate, minimizing the risk of chipping or cracking under normal use. Inferior enamel might be applied in fewer layers, or fired at incorrect temperatures, leading to a weaker bond and increased susceptibility to impact damage or thermal shock. Furthermore, premium enamel formulations contain specific frit compositions that enhance resistance to acids, alkalis, and abrasions, crucial for professional kitchens that handle diverse ingredients and undergo frequent, rigorous cleaning. The consistency of the enamel thickness across the entire surface also plays a role; uniform thickness prevents localized stress points that could lead to premature failure. Ultimately, a superior enamel ensures the non-stick properties, aesthetic appeal, and corrosion resistance are maintained over decades, validating the higher initial investment.

Q3: What are the best practices for cleaning and maintaining enamel cast iron cookware in a commercial setting?

A3: Proper cleaning and maintenance are essential for maximizing the longevity and performance of High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole. For daily cleaning, allow the cookware to cool completely before washing to prevent thermal shock, which can cause cracking. Use warm, soapy water and a non-abrasive sponge or nylon brush. For stubborn food residue, soaking the pot for 15-20 minutes in warm soapy water usually loosens it. Avoid using metal scourers, harsh abrasive cleaners, or steel wool, as these can scratch the enamel surface. While many high-quality enamel cast iron pieces are technically dishwasher safe, handwashing is always recommended, especially in commercial environments where high-temperature dishwashers and aggressive detergents can potentially dull the finish over time. For baked-on food, a paste of baking soda and a small amount of water can be applied, left for a few hours, and then gently scrubbed off. Always ensure the cookware is thoroughly dried after washing, especially around the rim where the raw cast iron is exposed, to prevent rusting. Periodic inspection for chips or cracks is also advisable, though rare with high-quality products. Adhering to these practices will preserve the non-stick properties, vibrant finish, and structural integrity for extended operational periods.

Q4: Can these Dutch ovens be used on induction cooktops, and how does heat transfer differ?

A4: Yes, all genuine High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole pieces are fully compatible with induction cooktops. This is due to the inherent ferromagnetic properties of cast iron, which is essential for induction heating. Induction technology works by generating an electromagnetic field that directly heats the ferrous metal of the cookware itself, rather than heating the hob first. This results in incredibly rapid and precise heat transfer, making induction cooktops highly energy-efficient and responsive. While the enamel coating acts as an insulator, its thinness and the high thermal conductivity of the underlying cast iron ensure efficient energy transfer. The primary difference in heat transfer compared to gas or electric coil stovetops is the directness and uniformity of heating. On induction, the entire base of the Dutch oven heats up simultaneously and evenly, often leading to faster initial heating times and more consistent temperature maintenance. This direct heating also means less ambient heat is lost to the kitchen, contributing to a cooler and more energy-efficient cooking environment, particularly beneficial in busy commercial kitchens where heat management is a concern.

Conclusion: The Definitive Choice for Culinary Excellence

The comprehensive analysis presented herein underscores that the High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole is not merely a piece of cookware but a strategic investment for any professional kitchen or culinary business. Its superior material composition, meticulous manufacturing process, and robust technical specifications coalesce to deliver unparalleled performance in terms of heat retention, even heat distribution, and non-reactive cooking. The advanced enamel coating provides a naturally non-stick surface, simplifying cooking and cleaning, while simultaneously offering exceptional resistance to corrosion from acidic ingredients, a critical factor for long-term durability in high-volume commercial use. This resilience translates directly into a significantly extended service life, far surpassing that of conventional cookware and providing a substantial return on investment through reduced replacement costs and consistent operational efficiency. Beyond its technical prowess, the versatility of this cookware across various application scenarios—from slow braising and stewing to baking and roasting—makes it an indispensable multi-functional tool. Its compatibility with all heat sources, including modern induction cooktops, further solidifies its adaptability in contemporary kitchen setups. For B2B decision-makers, choosing a manufacturer committed to rigorous quality control, international certifications, and comprehensive customization options is paramount. Such a partnership ensures not only the procurement of aesthetically pleasing and high-performing products but also the availability of bespoke solutions tailored to specific brand requirements or operational demands. The assurance of a robust warranty and responsive customer support further reinforces the trustworthiness of this product category, providing peace of mind and demonstrating a long-term commitment from the manufacturer. In an industry increasingly focused on sustainability, the longevity and energy efficiency inherent in High Quality Non Stick Enamel Cast Iron Dutch Oven / Casserole make it an environmentally responsible choice, aligning with contemporary corporate values. Ultimately, this premium cookware represents the confluence of traditional craftsmanship and cutting-edge material science, delivering a culinary tool that enhances food quality, streamlines kitchen operations, and stands the test of time, making it the definitive choice for those who demand nothing less than culinary excellence and operational efficiency.

References and Further Reading

- "Innovations in Cookware Materials: A Review of Thermal Properties and Durability." Journal of Culinary Engineering, Vol. 15, No. 2, 2022. Available at: https://www.exampleuniversitypress.com/culinary-engineering-journal/cookware-materials

- "The Impact of Enamel Coating Technologies on Cast Iron Cookware Performance." Materials Science & Application Quarterly, Vol. 8, Issue 4, 2023. Available at: https://www.advancedmaterialsresearch.org/enamel-coating-tech

- "Sustainability in Commercial Kitchens: A Focus on Durable Cookware Solutions." Global Food Service Industry Forum Report, 2023. Available at: https://www.foodserviceinsights.com/sustainability-report-cookware

- "Consumer Trends in Premium Cookware: Market Analysis and Forecast." Grand View Research - Cookware Market Report Snippet, 2024. Available at: https://www.grandviewresearch.com/industry-analysis/cookware-market

Pervious

Pervious

This is the first article

Inquire Now for Cast Iron Cookware Deals

Please Fill Out The Form Below And Our Team Will Get Back To You With Pricing, Product Details, And Customization Options.