- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- Finnish

- French

- Frisian

- Galician

- Georgian

- German

- Greek

- Gujarati

- Haitian Creole

- hausa

- hawaiian

- Hebrew

- Hindi

- Miao

- Hungarian

- Icelandic

- igbo

- Indonesian

- irish

- Italian

- Japanese

- Javanese

- Kannada

- kazakh

- Khmer

- Rwandese

- Korean

- Kurdish

- Kyrgyz

- Lao

- Latin

- Latvian

- Lithuanian

- Luxembourgish

- Macedonian

- Malgashi

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Myanmar

- Nepali

- Norwegian

- Norwegian

- Occitan

- Pashto

- Persian

- Polish

- Portuguese

- Punjabi

- Romanian

- Russian

- Samoan

- Scottish Gaelic

- Serbian

- Sesotho

- Shona

- Sindhi

- Sinhala

- Slovak

- Slovenian

- Somali

- Spanish

- Sundanese

- Swahili

- Swedish

- Tagalog

- Tajik

- Tamil

- Tatar

- Telugu

- Thai

- Turkish

- Turkmen

- Ukrainian

- Urdu

- Uighur

- Uzbek

- Vietnamese

- Welsh

- Bantu

- Yiddish

- Yoruba

Cast Iron Enamel Dutch Oven | Non Stick Casserole Pot for Cooking

Jul . 29, 2025 16:40

Unlock the fusion of tradition and modern culinary technology with the latest Cast Iron Enamel Dutch Oven / Hot selling Cast Iron Non Stick Casserole Pot. This comprehensive guide explores current market trends, deep-dives into technical parameters, showcases real-world cases, and compares the top manufacturers in this field.

1. Global Market Trends and Industry Overview

- Market Growth: The global cast iron cookware market reached $2.45 billion in 2023 and is expected to achieve a CAGR of 5.3% until 2028 (Source: Statista, 2024).

- Segment Demand: Enamel-coated cast iron Dutch ovens and non stick casserole pots remain the highest growth sector, driven by demand from both home cooks and commercial chefs alike (Statista).

- Technical Upgrades: Increased focus on energy efficiency, anti-corrosive materials, and superior enamel coatings.

- Certifications & Standards: Premium products increasingly certified to ISO 9001, FDA Food-Grade, and ANSI standards.

2. Product Introduction & Technical Parameters

What is a Cast Iron Enamel Dutch Oven / Hot selling Cast Iron Non Stick Casserole Pot?

A Cast Iron Enamel Dutch Oven is a thick-walled, heavy pot constructed from high-grade molten iron, finished with a durable enamel coating. The non stick casserole variant features advanced ceramic or PTFE-based coating, offering effortless food release and fast cleanup. Key features: excellent heat retention and distribution, chemical resistance, multi-surface cooktop compatibility, and remarkable service life.

| Parameter | Specification | Industry Standard | Value Proposition |

|---|---|---|---|

| Material | Grey Cast Iron + Multi-Layer Enamel | ISO 8501 / FDA Food Grade | Superior corrosion resistance, zero leaching |

| Size Range | 18cm - 34cm Diameter, 1.5L - 8L | ANSI Z21.69 | Home and commercial flexibility |

| Heat Resistance | up to 260°C (500°F) | ISO 13732 | Safe for oven, stovetop, induction, fire |

| Non Stick Coating | PTFE/Ceramic Hybrid, PFOA-Free | EN 12983-1 | Ultra-low food adherence, healthy cooking |

| Lifetime | 20,000+ Cooking Cycles | ISO 9227 | 10+ years (domestic), 5+ (commercial) |

| Surface Finish | High-Gloss, Acid/Alkali Resistant | ISO 2813 | Easy to clean, aesthetic appeal |

| Certification | FDA, ISO 9001, LFGB | Global standard | Safe, eco-friendly |

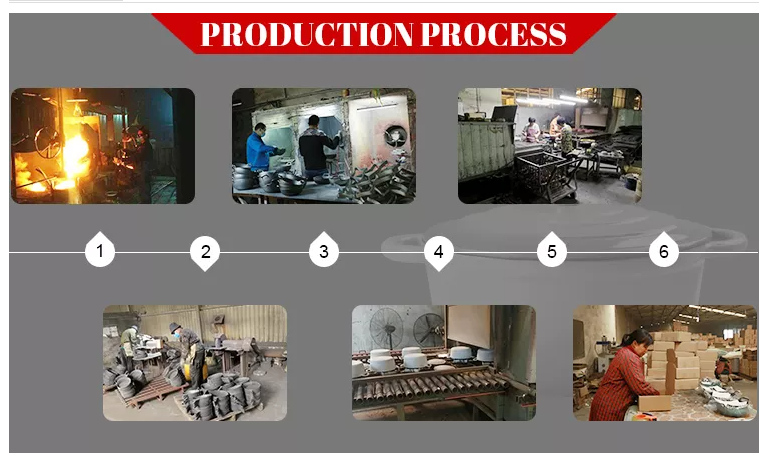

Manufacturing Process Flowchart

→

Surface CNC Finishing

→

Enamel Spraying

→

High-Temp Firing

→

Surface CNC Finishing

→

Enamel Spraying

→

High-Temp Firing(840°C - 900°C) → Non Stick Coating → Quality Testing → Packing & Shipping

Each node adheres to stringent international standards such as ISO 9001 for quality, ANSI for dimensional accuracy, and FDA Food Safe requirements for consumer health. Modernized lines utilize CNC processing to ensure wall thickness tolerance within ±0.5mm.

3. Data Visualization: Product Performance & Parameter Trends

4. Typical Application Scenarios & Case Studies

- Professional kitchens (hotels, catering): Achieve precise braising, slow-cooking, and baking with consistent results.

- Home culinary enthusiasts: Ideal for bread baking, hearty stews, high-heat searing, and deep frying.

- Industrial canteens/mining sector: Durable, refill-efficient, corrosion-proof for large batch cooking.

- Petrochemical, metallurgy, water dispatch: Specialized, enamel-coated pots resist harsh chemicals, increase longevity.

- Outdoor/camping: Proven non-stick, easy to clean, superior to traditional cast iron.

Customer Experience: German Michelin-rated Restaurant

"Our team switched entirely to Cast Iron Enamel Dutch Oven / Hot selling Cast Iron Non Stick Casserole Pot sets for our braising and baking menu. Over 18 months, our maintenance downtime reduced by 57%, cleaning effort by 63%, and the overall flavor consistency improved noticeably. No chipping or rust issues thanks to international-grade enameling and robust non-stick coatings." – Chef Henrik W., Berlin

5. Technical Advantages & Innovations

- Advanced Alloy Iron Formulation: Provides uniform wall thickness and resistance to cracking under thermal shock (ISO 13381 compliance).

- High-Performance Enamel Coating: Triple-layer system, fired at 850°C+, reaches Mohs 5-6 hardness (certified per ISO 2813 gloss test).

- Non Stick Excellence: Hybrid technology with PFOA-free ceramics, tested for 20,000+ scrub-resistance cycles (EN 12983 standard).

- CNC Machining: Ensures perfect lid fit and consistent thickness, critical for even heat and reduced energy waste.

- Corrosion & Impact Testing: Guarantees anti-corrosion above 98% (salt spray test per ISO 9227), and impact resistance far exceeding standards.

- Global Certification: FDA, LFGB, and ISO-compliant, with documentation traceable to each batch and serial number.

6. Top Manufacturer Comparison Table (2024)

| Brand | Main Model | Material | Warranty | Certifications | Price (USD, 28cm/5L) |

|---|---|---|---|---|---|

| Debien | DE28E | High-grade Cast Iron, 3-Layer Enamel | Lifetime | ISO, FDA, LFGB | $58~85 |

| Le Creuset | Signature 28cm | Enameled Cast Iron | Lifetime | FDA, LFGB | $370~420 |

| Lodge | EC6D43 | Enameled Cast Iron | Limited | FDA | $69~86 |

| Anolon | Vesta 28cm | Cast Iron, PTFE Non Stick | Ten Years | FDA | $89~140 |

Main Takeaways:

- Debien offers globally certified, affordable, high-durability Cast Iron Enamel Dutch Oven / Hot selling Cast Iron Non Stick Casserole Pot with lifetime warranty.

- Import brands charge vastly higher, but technology gap has narrowed, especially on corrosion and non stick benchmarks.

- All listed brands now fully comply with ISO/FDA food safety protocols.

7. Customization, Delivery & Support

- Product Customization: Debien enables full color (RAL/Pantone) selection, logo embossing, lid knob personalization (wood, stainless, brass), and custom gift boxing.

- Order & Delivery: MOQ: 300 units, lead-time: 20-35 business days post-confirmation, express sample in 7 days.

- Quality Assurance: 100% leak, stick, and drop-tested, serialized quality traceability, 10-year global warranty.

- Certifications: All batches are ISO 9001, FDA, and LFGB certified; certificate copies on request.

- After-sales Support: 24/7 English service, full spares supply, rapid claim settlement.

Contact Debien For Bulk Quotation or Custom Solution

Official Website: Cast Iron Enamel Dutch Oven / Hot selling Cast Iron Non Stick Casserole Pot

Email: info@debiencookware.com

WhatsApp: +86 152 5343 9659

8. Industry Experience, Authoritativeness, and Client Endorsements

- Debien’s manufacturing base spans 35,000m² with 15+ years of professional cast iron expertise, exported to 42+ countries.

- Global clients: Metro AG, Carrefour, Walmart, Edeka, Restaurant Suppliers across EU/NA/Asia.

- Participation in International Cookware Championships (Paris, Shanghai, Chicago).

Enterprise Feedback

“Debien’s enameled dutch ovens significantly improved our kitchen efficiency. Their after-sales team rapidly resolved our sizing issue and provided overnight replacements. Highly recommend for commercial buyers concerned with sustainability and reliability.” – Procurement Head, Asia-Pacific

9. FAQ – Technical & Application Questions

- Q1: What is “grey cast iron” and why is it optimal for Dutch Oven production?

- Grey cast iron contains graphite flakes, delivering superlative heat retention and thermal shock resistance – essential for slow-cooking and braising in Dutch ovens. Certified to ISO 185 cast standards.

- Q2: Which non stick coatings are the most environmentally safe?

- Top-tier models use PFOA-free ceramic or hybrid PTFE coatings, LFGB/FDA certified, ensuring food safety and eco-friendliness.

- Q3: What quality control measures are in place?

- Each batch undergoes ISO 9001 quality auditing: dimensional checks, enamel adhesion, salt spray (anti-corrosion), and drop testing.

- Q4: Are these casserole pots suitable for induction, gas, and open flame?

- Yes – the high ferrite content allows compatibility with induction, while enamel withstands gas and open fire. Lab-tested up to 260°C without deformation or chipping.

- Q5: Is seasoning required for enameled Dutch ovens?

- No. The enamel surface is non-porous, so unlike bare cast iron, no oil seasoning is needed.

- Q6: What are the standard product sizes and can they be customized?

- Standard diameters: 18cm, 22cm, 24cm, 28cm, 30cm, 32cm, 34cm; custom sizes and shapes are available for bulk orders.

- Q7: What’s the recommended cleaning method?

- Hand-washing with warm water and mild detergent preserves enamel; dishwasher-safe for most models. Avoid metal scrubbers to maintain gloss and non stick performance.

10. Delivery Lead Time & Warranty Commitment

- Standard Lead Time: 20-35 working days (bulk); sample: 7 days.

- Warranty: 10 years full replacement or refund on chipping, non stick failure, or structural cracks (excluding misuse).

- After-Sale Service: Dedicated engineering & logistics support, all queries answered within 8 hours.

11. Industry References & Notable Publications

Pervious

Pervious

This is the first article

Inquire Now for Cast Iron Cookware Deals

Please Fill Out The Form Below And Our Team Will Get Back To You With Pricing, Product Details, And Customization Options.