Cast iron cookware is made of iron and carbon alloy with carbon content of more than 2%. It is made by melting gray iron and casting the model. Cast iron cookware has the advantages of uniform heating, less oil smoke, less energy consumption, no coating is healthier, can do physical non-stick, do the dish color and taste better.cast iron cookwares have the advantage of being very durable. If they are used normally in home cooking, they can be used for more than ten or decades. They can be used as family heirlooms.

When it comes to the cookware, everyone is familiar with the cookware, whether you can cook or not, but when it comes to the type of cookware and production process, you may not be familiar with it. Today,I will give you a brief introduction which is about the production process of cast iron cookwares.

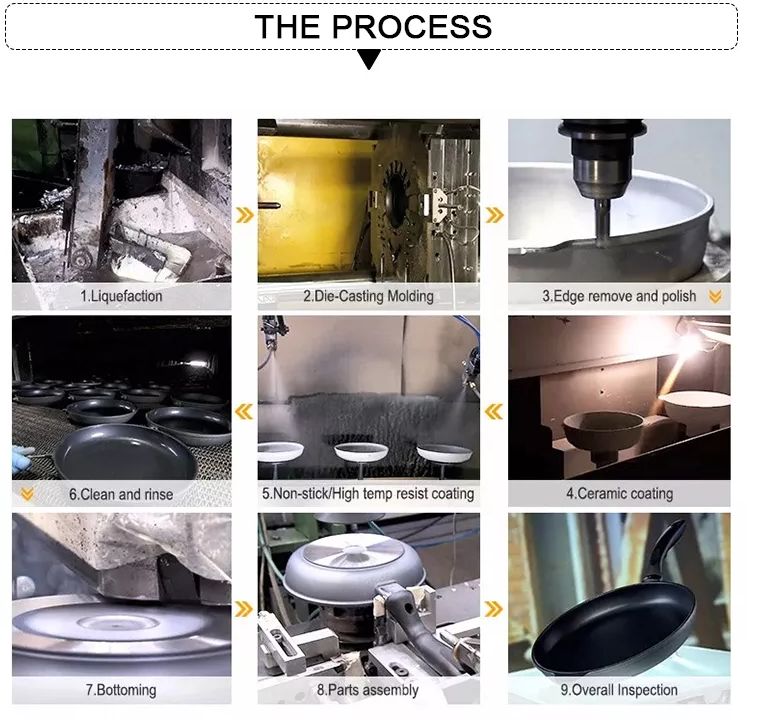

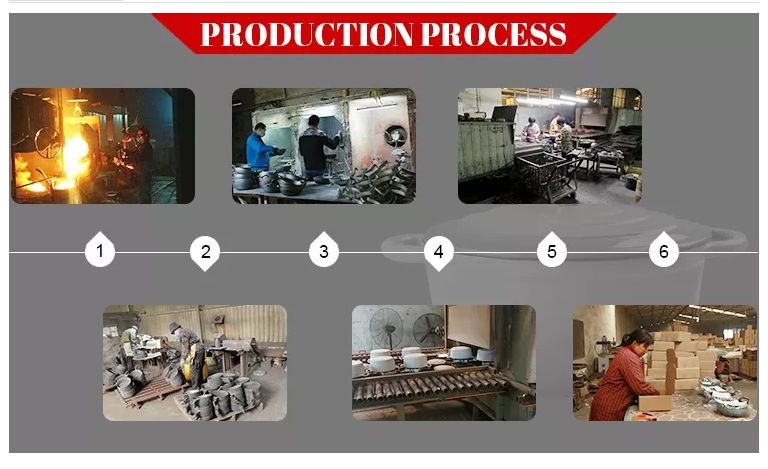

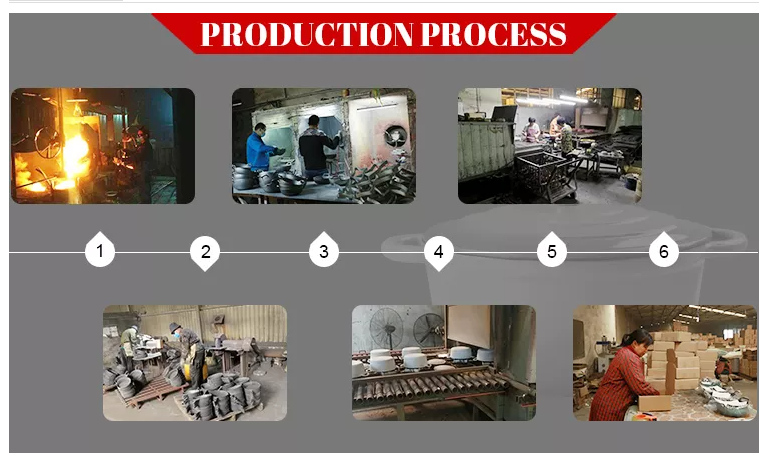

The production process of cast iron cookware includes the main steps of making sand mold, melting iron water, pouring, cooling molding, sand polishing and spraying.

Making sand molds: Since it is cast, you need molds. The mold is divided into steel mold and sand mold. The steel mold is made of steel according to the design drawings or samples. It is the mother mold. Sand mold production can be purely manual or automatic production with equipment (called Di sand line). Before, there were more manual production, but now they gradually start to use equipment production. First, the efficiency is greatly improved, the quality is more stable, and the labor cost is more and more expensive. A skilled worker can only make one or two hundred sand molds a day, while the equipment can make thousands a day, the efficiency difference is very obvious.

Di sand line is designed by Di sand Comcookwarey in Denmark and authorized for domestic production. A complete set of equipment is worth tens of thousands of yuan. All the comcookwareies using this automatic production equipment are slightly larger. But Di sand line is not universal, some complicated cookware type or deep cookware, Di sand line can not be achieved, or need manual, these two points are also the reason why manual is not completely eliminated. Manual production is manually filled with sand in the steel mold, by pressing, so that the sand is tightly combined to form the shape of the cookware. This process tests the skills of the workers: whether the humidity of the sand is appropriate or not, and whether the pressure is tight or not, affect the shape and quality of the cookware.

Molten iron water: Cast iron cookwares generally use gray cast iron, in the shape of a long bread, also known as bread iron, according to the content of carbon and silicon, there are different models and performance. The iron is heated to above 1250℃ in a heating furnace to melt into molten iron. Iron melting is a process of high energy consumption. In the past, it was through burning coal. In recent years, due to the serious environmental inspection, large factories have basically switched to electric heating. Molten iron is melted at the same time as or slightly earlier than the sand mold.

Casting molten iron: the molten iron is transferred to the sand mold by equipment or workers to pour into the sand mold. The casting of molten iron is completed by machines in large foreign and domestic comcookwareies, and by workers in small comcookwareies. Workers use a ladle-like thing, first pour the big bucket of molten iron into the small ladle, and then from the ladle into a sand mold one by one.

Cooling molding: The molten iron is cast and allowed to cool naturally for 20 minutes to form. This process continues to melt the molten iron and wait for a new sand mold.

Removing sand mold and grinding: wait for the hot metal to cool and form, enter the sanding equipment through the conveyor belt sand mold, remove the sand and excess scraps through vibration and manual processing, and a wool return cookware is basically formed. Blank cookware needs to go through rough grinding, fine grinding, manual grinding and other steps, in order to completely remove the sand on its surface and polish relatively smooth and smooth, and remove the rough edge of the edge and the place that is not easy to polish by manual grinding. Manual grinding has high technical requirements for workers, and this type of work is also the highest wage in the whole process.

Spraying and baking: The polished cookware enters the spraying and baking process. Workers spray a layer of vegetable oil (edible vegetable oil) on the surface of the cookware, and then enter the oven through the conveyor belt to bake for a few minutes, and a cookware is formed. The surface of the cast iron cookware is sprayed with vegetable oil to bake in order to seep the grease into the iron pores, forming a black rust-proof, non-stick oil film on the surface. The surface of this layer of oil film is not coating, in the process of use also need to maintain, properly used cast iron cookware can do not stick. In addition, the enamel cookware is the same as the cast iron cookware before the spraying process, except that instead of vegetable oil, the enamel glaze is sprayed in the spraying process. The enamel glaze needs to be sprayed two or three times, each time it needs to be roasted at a high temperature of 800 degrees, and finally the colorful enamel cookware is formed. Then it’s time to check it out and package it out, and a cookware is made.

This article is just a simple description, the actual production is far more complex than described in this article. The whole production process of the cast iron cookware looks very simple, and you will know the difficulties when you really start the production process.

Thank you very much for reading. I will continue to update more articles about cast iron cookware in the future. comments are welcome.