Durable Enameled Cast Iron Steak Frying Pans | Perfect Sear

Aug . 18, 2025 06:20

The Enduring Appeal of Cast Iron Enameled Cookware in Professional Settings

In the dynamic world of professional culinary arts and high-end hospitality, the choice of equipment profoundly impacts operational efficiency, dish quality, and overall customer satisfaction. Among the myriad of cookware options, Cast iron enameled steak frying pans / frying pots stand out as a cornerstone for their unparalleled thermal performance, durability, and aesthetic appeal. These robust culinary tools are not merely cooking vessels; they represent a significant investment in quality, offering exceptional heat retention and distribution, which are critical for achieving perfect searing, braising, and slow cooking results consistently. The meticulous design and material science behind these pieces ensure they meet the rigorous demands of commercial kitchens, from bustling restaurants to exclusive catering services. Understanding the intrinsic value and advanced engineering of these specialized pans is crucial for procurement managers and executive chefs looking to optimize their kitchen infrastructure for long-term success and superior culinary output.

The market for high-performance cookware has witnessed a steady evolution, with a discernible shift towards materials that offer both traditional benefits and modern convenience. Cast iron, a material celebrated for centuries for its heat-management properties, has been elevated through the application of enamel coatings, mitigating common issues like rusting and reactive surfaces. This fusion of ancient material and contemporary finishing techniques results in cookware that is not only highly functional but also remarkably resilient and easy to maintain, a vital consideration for high-volume environments. The demand for such specialized equipment transcends basic utility, extending into areas where precise temperature control and even cooking are paramount. This includes environments ranging from steakhouses requiring perfect crusts on meats, to gourmet restaurants utilizing slow-cooking techniques for complex sauces and stews. Furthermore, the inherent longevity of properly maintained Cast iron enameled steak frying pans / frying pots contributes to a reduced total cost of ownership over time, making it a fiscally sound choice for businesses aiming for both operational excellence and financial prudence.

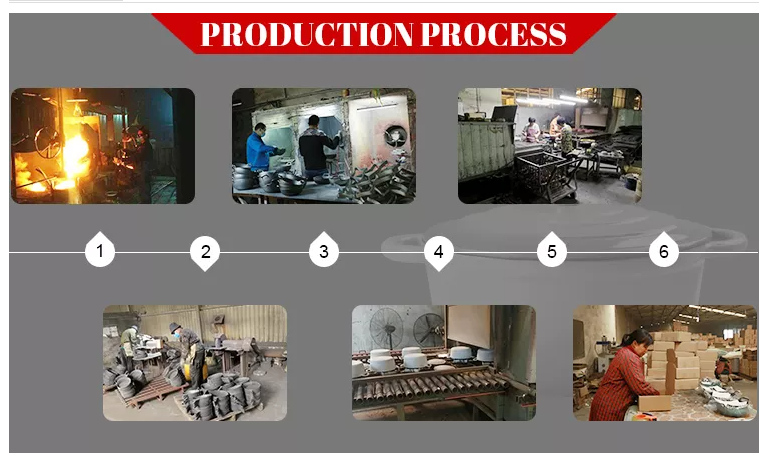

Advanced Manufacturing: Precision and Durability in Every Pan

The production of high-quality Cast iron enameled steak frying pans / frying pots is a sophisticated process that merges traditional craftsmanship with modern engineering precision. It typically begins with the careful selection of raw materials: high-grade pig iron, often supplemented with steel scrap, ensuring optimal carbon content and purity for casting. The primary manufacturing process involves sand casting, where molten iron, heated to temperatures exceeding 1,500°C, is poured into meticulously prepared molds, accurately forming the pan's shape and structure. This foundational step is critical for achieving the desired thermal mass and structural integrity. Following casting, the rough castings undergo a series of finishing operations, including shot blasting to remove sand and scale, grinding to smooth edges and surfaces, and meticulous deburring to eliminate any imperfections. These preparatory stages are crucial to ensure a flawless surface for the subsequent enameling process.

The enameling phase is where the cookware acquires its distinctive aesthetic and functional properties. After thorough cleaning and pre-treatment, a base coat of frit, a glass-like powder, is applied and then fired at extremely high temperatures (around 800°C - 900°C) to fuse it with the cast iron substrate, creating a strong, non-porous bond. This initial layer provides corrosion resistance and prepares the surface for subsequent color coats. Multiple layers of colored enamel are then applied, each fired individually, to build up a robust, chip-resistant, and aesthetically pleasing finish. Quality control is paramount at every stage, with inspections ranging from visual checks for surface defects and color consistency to more technical assessments like adhesion tests, thermal shock resistance, and acid resistance, ensuring the enamel can withstand the rigors of professional kitchen environments. Compliance with international standards such as ISO 9001 for quality management systems and ANSI for specific product performance specifications is rigorously maintained, underscoring the product's reliability and extended service life. The lifespan of properly maintained Cast iron enameled steak frying pans / frying pots can extend for decades, offering exceptional value in demanding industrial culinary settings where durability is as critical as performance.

Technical Specifications and Performance Benchmarks

The superior performance of Cast iron enameled steak frying pans / frying pots in professional culinary applications is directly attributable to their specific technical parameters and inherent material properties. Understanding these specifications is crucial for professionals seeking optimal cooking outcomes and long-term investment value. The core attribute is thermal conductivity and heat retention; cast iron excels at absorbing and retaining heat, distributing it evenly across the cooking surface, which is vital for consistent searing and browning, preventing hot spots that can lead to unevenly cooked food. The enamel coating, while affecting initial heat-up time slightly, provides a non-reactive, non-stick-like surface (when properly seasoned over time), protecting the iron from rusting and allowing for a wider range of acidic ingredients to be used without metallic taste transfer.

The robust nature of these pans means they possess an exceptional resistance to warping, denting, and scratching, common pitfalls with lighter-gauge cookware, ensuring a flat cooking surface for consistent results over time. This makes them particularly suitable for high-traffic environments like commercial kitchens, where equipment longevity and consistent performance are paramount. Furthermore, the non-reactive enamel surface ensures that foods, especially acidic ingredients like tomatoes or wine, can be cooked without absorbing metallic flavors, preserving the integrity of complex culinary creations. The specific heat capacity of cast iron allows it to maintain consistent temperatures for extended periods, making it ideal for processes requiring stable heat, such as simmering, braising, or slow-roasting. The integration of advanced material science, borrowed from the stringent requirements of sectors like metallurgy for material integrity and analysis, into cookware production underscores the commitment to durability and high performance that professionals demand.

Versatile Applications and Industry Benefits

Cast iron enameled steak frying pans / frying pots are exceptionally versatile tools, finding indispensable roles across a broad spectrum of B2B applications, primarily within the professional culinary and hospitality sectors. Their superior heat retention and even heat distribution make them ideal for searing steaks to perfection, achieving that desirable crust while keeping the interior juicy. Beyond steaks, they excel in slow-cooking methods such as braising short ribs, simmering rich stews, or baking artisan breads, thanks to their ability to maintain stable temperatures over extended periods. Restaurants, hotels, catering companies, and culinary schools heavily rely on these pans for consistent, high-quality output, where the cookware's performance directly translates into culinary excellence and customer satisfaction. The robust construction ensures they can withstand the rigorous daily use and cleaning cycles typical of high-volume commercial kitchens, distinguishing them from consumer-grade alternatives.

The benefits extend beyond mere cooking performance. For instance, the enamel coating provides excellent corrosion resistance, a vital feature in humid kitchen environments and during cleaning, significantly extending the product's lifespan compared to raw cast iron. This anti-corrosion property is akin to the protective coatings used in industrial sectors like petrochemicals and water supply systems, where material integrity against corrosive agents is non-negotiable for operational longevity and safety. While these pans are not used in actual petrochemical plants, the underlying engineering principles of material science and protective layering mirror those high-demand environments. Furthermore, the efficient heat transfer capabilities of cast iron contribute to energy savings in professional kitchens by optimizing cooking times and requiring less sustained heat input once desired temperatures are achieved. This translates into tangible operational cost reductions, a significant advantage for businesses focused on sustainability and efficiency. The aesthetic versatility of enameled cast iron also allows for seamless transition from kitchen to table, making them perfect for serving dishes directly, enhancing presentation and maintaining food temperature for guests.

Manufacturer Comparison and Customization Solutions

When sourcing Cast iron enameled steak frying pans / frying pots for B2B applications, comparing manufacturers goes beyond just price; it involves assessing material quality, manufacturing consistency, adherence to international standards, and the breadth of customization options. Leading manufacturers distinguish themselves through superior casting techniques that minimize impurities and defects, resulting in a denser, more uniform iron body. Their enameling processes involve multiple layers and rigorous firing schedules to ensure chip resistance, vibrant color retention, and a non-reactive surface that meets stringent food safety standards such as FDA and LFGB. Furthermore, top-tier suppliers offer comprehensive warranty programs and robust after-sales support, reflecting their confidence in product longevity and commitment to client satisfaction. Evaluating a manufacturer’s service history, certifications, and direct client testimonials provides crucial insights into their reliability and the real-world performance of their products in demanding culinary environments.

For B2B clients, particularly hotel chains, restaurant groups, or culinary institutions, the ability to customize cookware offers significant brand differentiation and operational advantages. Reputable manufacturers provide extensive customization solutions for Cast iron enameled steak frying pans / frying pots, including bespoke sizing, specific color matching to corporate branding, and the incorporation of custom logos or engravings on handles or bases. This level of personalization not only enhances brand visibility but also contributes to a cohesive identity across culinary operations. For example, a luxury hotel might require a specific shade of blue to match its interior design, or a restaurant chain might want its emblem cast into the pan handle for a premium touch. Such tailored solutions require advanced manufacturing capabilities, including precision tooling and flexible production lines, ensuring that custom orders meet the same high-quality standards as standard products. Debien Cookware, for instance, leverages years of expertise and state-of-the-art facilities to deliver bespoke solutions that meet the precise aesthetic and functional requirements of its B2B partners, reinforcing their market position through unique and high-performing culinary tools.

Quality Assurance, Certifications, and Trustworthiness

In the procurement of professional-grade cookware, assurance of quality and adherence to global standards are non-negotiable. For Cast iron enameled steak frying pans / frying pots, this involves rigorous testing protocols and certifications that validate their safety, durability, and performance. Reputable manufacturers operate under ISO 9001 quality management systems, ensuring consistency from raw material sourcing to finished product. Furthermore, compliance with food-grade safety standards like FDA (U.S. Food and Drug Administration) and LFGB (German Food, Articles of Daily Use and Feed Code) is crucial, guaranteeing that the enamel coating is lead and cadmium-free, non-toxic, and non-reactive, preventing any leaching of harmful substances into food. Independent lab testing often verifies parameters such as thermal shock resistance, abrasion resistance, acid and alkali resistance, and heavy metal content, providing objective data on product performance and safety. These certifications not only demonstrate a commitment to excellence but also provide peace of mind for B2B buyers who prioritize the health and safety of their patrons and staff.

Building trust with B2B clients extends beyond product quality to encompass reliable service and support. This includes transparent delivery schedules, clear warranty policies, and responsive customer service. A typical delivery cycle for standard orders of Cast iron enameled steak frying pans / frying pots might range from 4-6 weeks, with customized orders potentially requiring 8-12 weeks, depending on complexity and volume. Manufacturers often provide a limited lifetime warranty against manufacturing defects, demonstrating confidence in their product's longevity and quality. Comprehensive customer support, including technical assistance for care and maintenance, and a streamlined process for addressing any product-related inquiries, further solidifies a manufacturer's trustworthiness. For example, Debien Cookware prides itself on its decades of service in the cookware industry, backed by an extensive network of satisfied commercial clients and a steadfast commitment to delivering not just a product, but a complete solution that includes expert advice and unwavering post-purchase support. This holistic approach ensures that B2B partners receive reliable products and equally reliable service.

Frequently Asked Questions (FAQs)

Q1: How does enameled cast iron compare to traditional cast iron in terms of maintenance?

A1: Enameled cast iron significantly reduces maintenance requirements compared to traditional, bare cast iron. Bare cast iron requires regular seasoning to build a non-stick layer and prevent rust, and it is highly susceptible to rust if not properly dried and oiled. Enameled cast iron, conversely, is non-reactive and does not require seasoning, making it much easier to clean and resistant to rust. Its smooth, glass-like surface prevents food from sticking and allows for use with acidic ingredients without any metallic taste transfer, a common issue with unseasoned bare cast iron. While bare cast iron offers slightly superior initial searing temperatures, enameled versions provide a more versatile, low-maintenance, and hygienic option for professional kitchens.

Q2: Are these pans suitable for all heat sources, including induction?

A2: Yes, Cast iron enameled steak frying pans / frying pots are universally compatible with all heat sources. Their ferromagnetic properties make them perfectly suitable for induction cooktops, allowing for efficient energy transfer and precise temperature control. They can also be used on gas, electric coil, ceramic, and radiant stovetops, as well as in ovens and under broilers, typically up to temperatures of 260°C (500°F). This versatility makes them an invaluable asset in any modern professional kitchen, capable of adapting to various cooking methods and equipment setups without compromising performance.

Q3: What is the typical lifespan of a high-quality enameled cast iron pan in a commercial setting?

A3: With proper care and maintenance, a high-quality Cast iron enameled steak frying pans / frying pots can last for decades, often exceeding 20-30 years in a commercial setting. The robust cast iron core and durable enamel coating are designed to withstand the rigors of heavy daily use, thermal cycling, and frequent cleaning cycles common in professional kitchens. While minor aesthetic wear might occur over time, the structural integrity and cooking performance are preserved. Investing in premium enameled cast iron cookware significantly reduces the frequency of replacement, offering a substantial long-term cost saving compared to less durable alternatives. Manufacturers often provide extensive warranties, underscoring this longevity.

Q4: Can custom branding be applied to these pans for B2B orders?

A4: Absolutely. Many manufacturers specializing in B2B cookware solutions offer extensive customization options, including custom branding for Cast iron enameled steak frying pans / frying pots. This can involve engraving or casting corporate logos onto the handles or bases of the pans, selecting specific enamel colors to match brand aesthetics, or even developing unique sizes and shapes. Customization serves as an excellent way for hotel chains, restaurant groups, or culinary institutions to reinforce their brand identity, create unique kitchenware, and ensure consistency across their operations. It requires a manufacturing partner with flexible production capabilities and a strong design team.

Future Trends and Conclusion

The trajectory of the professional cookware market points towards an increasing emphasis on sustainability, multifunctional design, and integrated technology. For Cast iron enameled steak frying pans / frying pots, this translates into innovations aimed at reducing their environmental footprint, enhancing user ergonomics, and potentially incorporating smart features for temperature monitoring. Manufacturers are exploring more eco-friendly enamel formulations and optimizing casting processes to minimize waste and energy consumption. There's also a growing demand for versatile designs that can transition seamlessly from cooktop to oven to table, supporting modern culinary trends that prioritize visual appeal alongside performance. As culinary establishments continue to seek equipment that offers both aesthetic appeal and robust, consistent performance, enameled cast iron cookware will undoubtedly remain a premium choice, evolving to meet new demands while retaining its core attributes of durability and superior heat management.

In conclusion, investing in high-quality Cast iron enameled steak frying pans / frying pots is a strategic decision for any professional culinary operation focused on long-term value, exceptional performance, and consistent culinary output. Their intricate manufacturing process, robust technical specifications, and broad applicability across diverse cooking methods make them indispensable tools. Supported by rigorous quality assurance, comprehensive certifications, and reliable after-sales support, these pans offer unparalleled trustworthiness and return on investment. As the industry advances, this class of cookware will continue to be a benchmark for quality, embodying a perfect fusion of traditional strength and modern culinary demands.

References

- International Organization for Standardization (ISO). (2020). ISO 9001:2015 Quality management systems — Requirements.

- U.S. Food and Drug Administration (FDA). (2023). Food Contact Substances (FCS).

- Deutsches Lebensmittel- und Futtermittelgesetzbuch (LFGB). (2021). Food and Feed Code.

- American National Standards Institute (ANSI). (2023). Overview of ANSI Standards Development.

- ASM International. (2018). ASM Handbook, Vol. 15: Casting.

- The American Ceramic Society. (2022). Vitreous Enamel Technology and Applications.

Pervious

Pervious

This is the first article

Inquire Now for Cast Iron Cookware Deals

Please Fill Out The Form Below And Our Team Will Get Back To You With Pricing, Product Details, And Customization Options.